We implement Computer Vision systems to inspect harvested produce for defects. These systems use advanced image recognition to detect imperfections such as bruises, blemishes, and size variations. Automated quality control ensures that only the highest quality products are selected for further processing and packaging, maintaining high standards and consumer satisfaction.

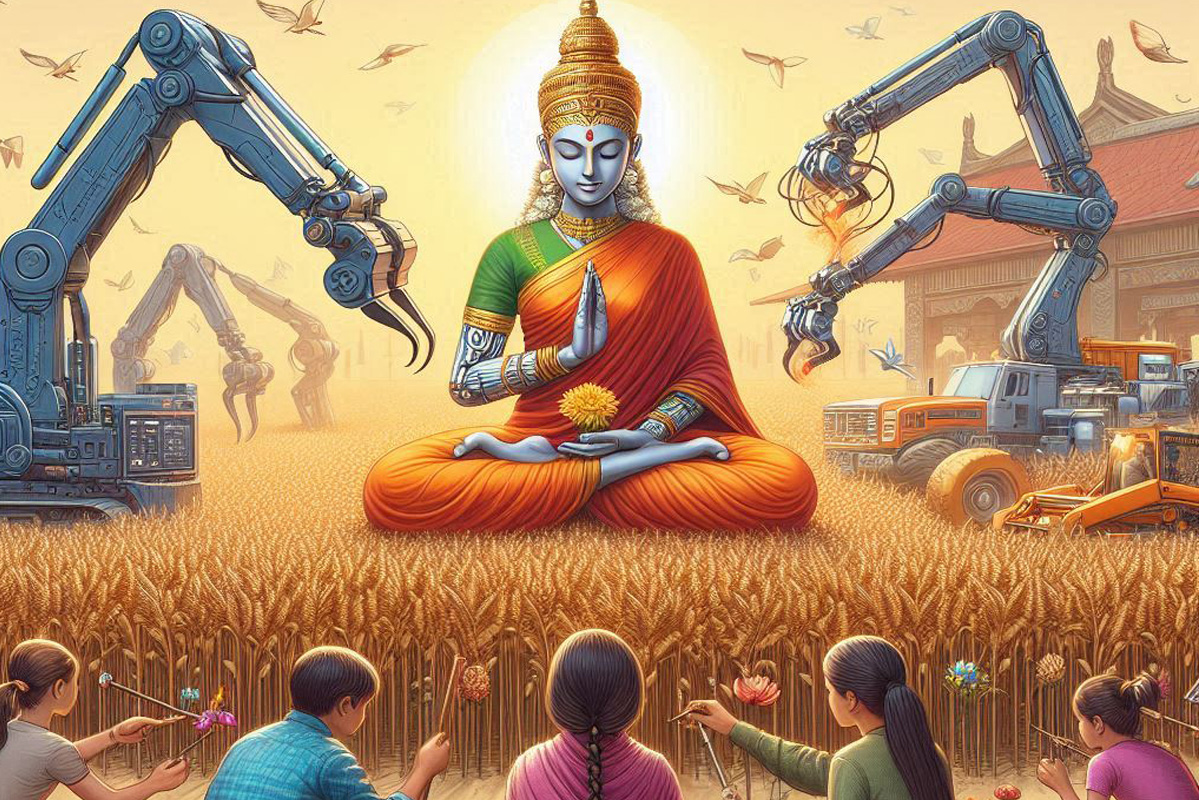

Robotic arms and conveyor systems automate the sorting, grading, and packaging of harvested crops. This automation streamlines post-harvesting operations, reducing manual labor and increasing efficiency. Automated systems ensure consistency and speed in processing, enabling large volumes of produce to be handled quickly and effectively.

Utilizing IoT sensors and blockchain technology, we provide complete traceability of produce from farm to fork. Each product is tracked through every stage of its journey, ensuring transparency and accountability. This traceability enhances food safety, builds consumer trust, and allows for quick identification and resolution of any issues that may arise in the supply chain.